Read This Before Investing in Mesh Decking

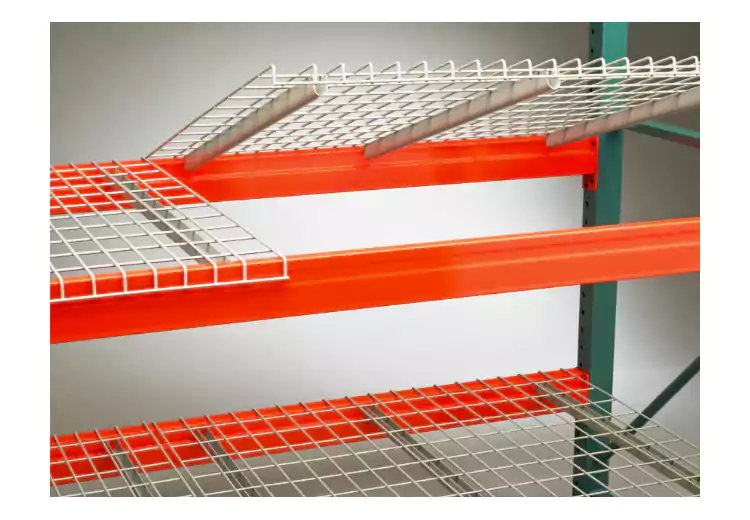

By definition, a pallet rack always has vertical frames and cross beams as its 2 primary parts. Crossbeams hold loads placed on the racking and aid in system stability, while vertical frames provide a structural framework. However, there’s a high probability you’ll want to install some kind of wire mesh decking on your cross beams if you want to equip your pallet rack, which we assume you will.

Although the two beams are sturdy, they don’t offer much surface area against which to put loads or, for that matter, the potential for error.

What are Wire Mesh Decks?

Pallet rack shelving systems usually use industrial product wire decking. They are intended to give more support to the pallets which are being kept in the storage system. As it can serve as a support system for any workloads which might be unsafe, wire decking may also have safety considerations. Our industrial wire decking is comprised of welded wire mesh and frequently includes reinforcing channels or supporting wires. The wire decks are supported by rack beams from the front and back of the rack system.

Ordering Wire Mesh Decks: Some Important Steps

One can add a variety of decking materials to their pallet rack system, but we advise wire mesh decking because it is commonly regarded as the industry standard.

The procedure for obtaining pallet rack wire decking has been outlined in a succinct, uncomplicated manner by us. Fortunately, buying wire decking is a rather simple process for those who are interested.

Decide on your channel’s look

The “channels” that hold wire mesh decking come in two variations: U Channel and Flare Channel. The kind of pallet rack beam that the decking will rest on will determine the kind of channel you require.

Determine the length of your pallet rack cross beam

The dimension of your pallet rack cross beam needs to be determined. It’s an easy and fast procedure.

From front to back, examine your upright

You must determine the depth of your uprights in order to determine the precise specifications for your wire decking. This is done by measuring from the outside in one upright end around the outside of the second side of the same upright.

The breadth of your beam’s top should be measured

The width of the front of your pallet rack cross beam should be measured next. It is essential to take a precise count because there is no set width for the top of a pallet rack crossbeam.

Your beam step’s depth should be measured.

You should measure the diameter and depth of the beam step, or the depth from the surface of the beam where the beam becomes broader, after measuring the dimensions of your beam’s top.

Calculate the required peak capacity for each pallet position

Determine how much space you’ll need for each pallet location at the total potential. The figure you compute for this stage will depend critically on what you intend to place on the rack, which is a very self-explanatory procedure.

Find the RIGHT manufacturer for your pallet rack

Find out who made the pallet rack that the wire decking will be attached to. This is typically accomplished by scanning the rack system for a brand or title stamp, but it can also be accomplished by using a search on google or a pallet rack guide.

If available, locate all the part numbers for your rack system

Find every part number on your specific rack system, if it is possible.

Determine how many wire decks you require

Lastly, determine the number of wire decks you’ll need before placing your order. Per pallet position, there is typically one wire deck.

Get in Touch with ALA Logistics!

Looking to invest in wire mesh decks for your pallet racks? Or do you have any questions related to wire decking?

Feel free to reach our customer support to know more about wire mesh decks. Don’t forget to check out our blogs for helpful tips and information on wire containers, pallet racks and other warehouse or logistics-related topics.