Wire Mesh Containers— How Auto and Tire Industry Can Reduce Costs with Material Handling Equipment?

Before buying wire mesh containers, let’s have a brief look at how they can help automotive industries.

The logistics, warehousing and storage industry keeps going up each year. And the automotive sector is no exception. Several supply chain disruptions and record prices have been brought on by the COVID-19 epidemic. The average price per new-car transaction grew significantly this year alone, partly to higher gasoline costs and greater demand.

Wire Mesh Containers Cuts Down the Cost and Efforts Too!

What then can auto and tire warehouses do to keep costs down when almost everything seems to be more expensive now than it once was? In the automobile sector, purchasing top-quality warehousing equipment from experienced warehousing, storage and logistics solutions manufacturer is an excellent way of saving money.

Disposable transporting materials such as plastic wrap and cardboard boxes will cost you more in the long term compared to sustainable packaging and transporting solutions.

Explore more about how to save money by purchasing the right warehouse automotive equipment, from shipping to receiving, and everything in between.

Portable Rack System for Storing Parts and Materials

A pallet rack system with multiple shelves is required in every warehouse to store products and parts. Depending on the quantity of your inventory, you must select a style. When storing bulky goods like tyres, doors, and automobile frames, look for top-grade portable and stackable racks with a high weight capability.

For tyres, beam racks are frequently the best option. They come with substantial cross beams on which you may put your goods. Pallets containing heavy objects can also be stored on these racks.

Portable storage racks are widely used in automobile and tire facilities to arrange products onto different tiers. These racks come in a wide range choice of racks and shelves for smaller components and supplies. Your personnel will easily be able to tell the difference between one segment from another one if your products are divided into various levels.

For holding various products and supplies, standard stack racks work great. If the customer is selecting smaller goods one at a time, you can put storage containers right on the shelf. If you need to use a forklift to transfer a lot of merchandise, put the container on a pallet.

When selecting a rack solution, take the size and layout of your warehouse into account. As your storage requirements change, the racks should be simple to move and reorganize. Find storage racks that attach to the floor for enhanced durability if you want to put the racks in place.

Stack racks are often constructed from materials that are incredibly resilient and long-lasting. When rebuilding or enlarging your automobile warehouse, you might save hundreds of dollars by purchasing old racks. Take full advantage of your storage investment by buying top-quality stack racks.

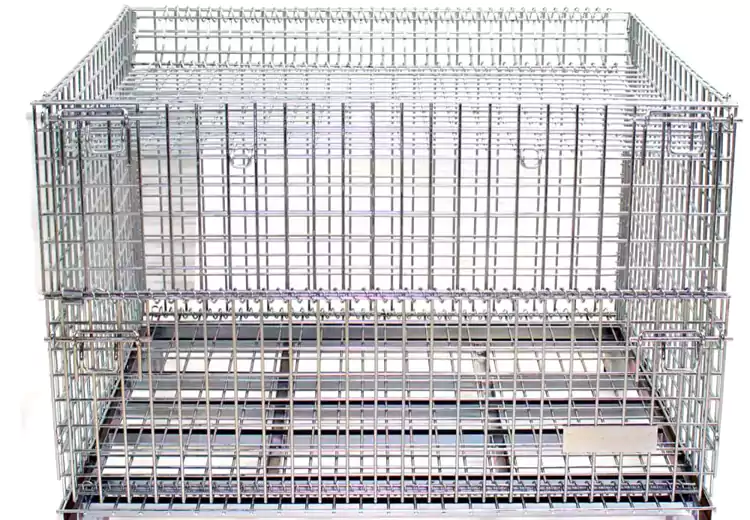

Collapsible Container for Delivering Products and Sorting

In the warehousing sector, space is a constant problem. The price of renting warehouse space keeps going higher each year as more products move through the supply chain. Your warehouse is largely made up of your containers. Based on the circulation of items, which might be hard to forecast, they will enter and exit rotation.

The use of reusable foldable containers is therefore recommended. They are often constructed using premium materials. When extra orders arrive, your team may instantly install these containers. The container’s walls simply need to be pulled apart, and they won’t need to do anything else.

Compared to stiff transport or storage materials, a collapsible container is more space-efficient. For quicker unloading times, you can stack them against the wall or put them on a rack next to the docking station.

Compared to plastic crates or cardboard boxes, they are also less expensive and simpler to utilize. The box won’t need to be put together and disassembled by your team at the end of the day. Such collapsible containers and wire mesh containers can be used repeatedly without causing damage to your stock.